One-stop production and sales

It is possible to have a one-stop request for design, material selection, knitting, and processing that can only be done at a manufacturing plant.

We minimize the loss of time and money due to outsourcing of business, and respond quickly to requests for design modifications.

Our strength in being able to resolve customer requests smoothly and speedily has led to deep trust.

Product Planning Department

When planning various products, the top priority is to secure the “protection” and “warming” functions of the feet, which is the original purpose of socks.

Warming your feet is an important factor for a healthy life. Protecting your feet from scratches and impacts is also an important function of socks.

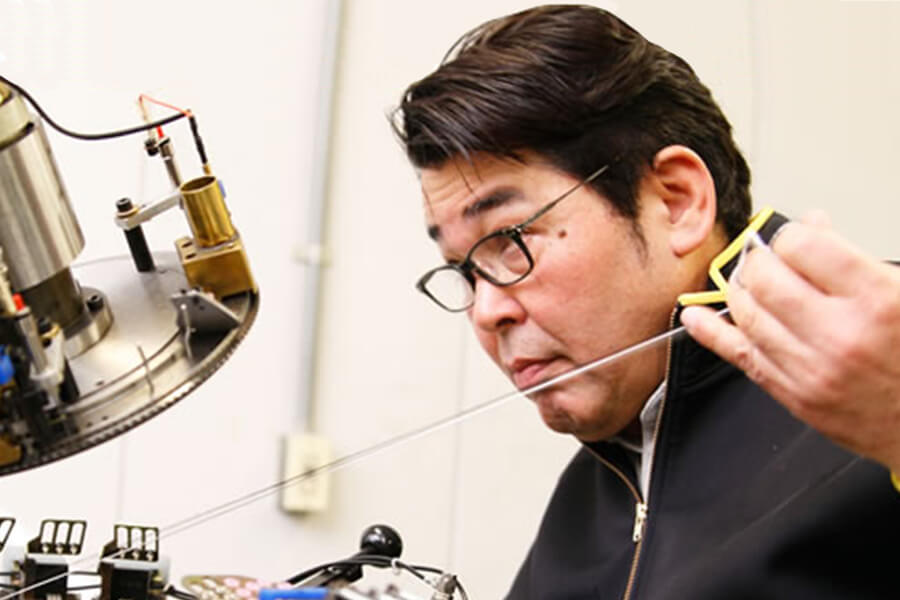

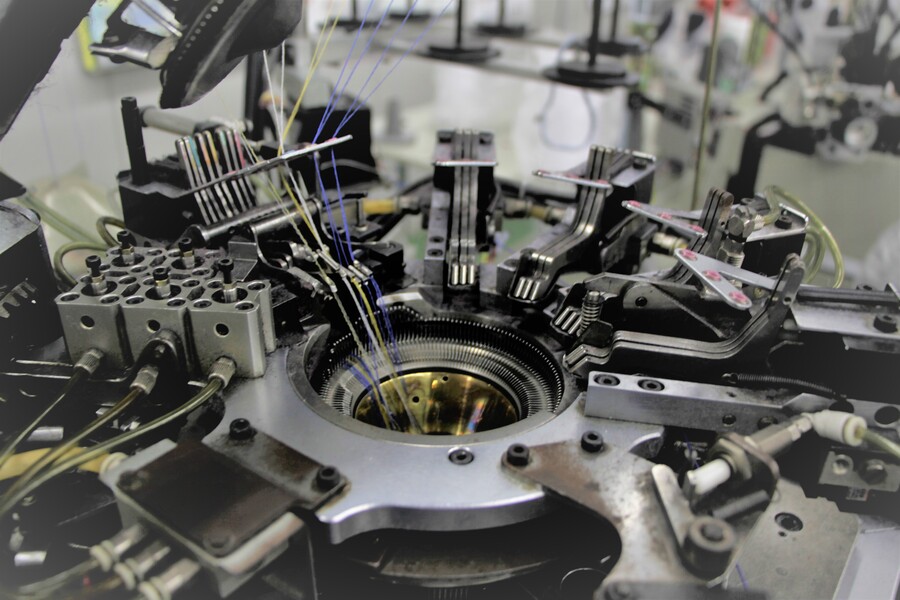

In-house production line

Ueda Co., Ltd. is equipped with a full range of production equipment, including the latest knitting machines manufactured by Lonati of Italy, and produces high-quality socks with full operation every day.

The reliability has been certain since we have been contracting OEM production of major famous manufacturers for many years.

EC shop

Utilizing our high technology and product development capabilities, we want to deliver better products to customers more quickly. With that in mind, we are focusing on direct sales on the Internet.

Until now, we mainly sold at Rakuten Ichiba and Amazon, but we opened our own EC site in January 2020.

We will continue to focus on direct sales of our own brand products that do not include any external margins in order to fulfill our customers’ wishes.

Low risk product planning

In addition to our own brand manufacturing, we support customer product development and custom-made products.

Leveraging our product development know-how, we will propose the best products for you considering the cost while keeping close to your wishes.

Please tell us what you want, such as “I want to make such a product!”

Can manufacture a small number of samples because of in-house manufacturing

We will formulate specifications based on product planning documents and create sample products according to these specifications.

We have a track record of making original products for sports teams such as baseball and soccer since our founding.There are not many members of the sports team. So when it comes to reorders, it happens in pairs.

Through this experience, our company has established a system (system) for producing small lot products regardless of whether it is for sports or not.

Create multiple project samples and test products

In order for a brand to survive, it is important not only to make it, but also to satisfy users.

In order to verify that a product is something you want to use again, it is essential to run multiple projects in parallel and verify.

Being able to do this with a sense of speed will directly lead to modern brand competitiveness.

Test sales available in small lots

At our company, we make socks every day with the desire to “close to customer’s problems and lead to solutions”.

- “Isn’t it impossible to make such a sock?”

- “Because it’s a small lot, I’m not going anywhere.”

Ueda’s strength lies in its technical and manufacturing capabilities that can solve these problems.

Fastest product flow

We will conduct hearings based on the inquiries we receive and ask for customer requests.We will hold a detailed meeting with details such as the concept, the number of production lots (from 100 pairs) and the release time.

Based on the content, we will consult and propose materials and design reproduction.

After receiving additional requests and corrections, we will discuss the quotation and production schedule, and proceed to confirm the quotation and schedule.

Technology that can shape ideas

In order to realize products that can be used with peace of mind, we always conduct strict inspections along the manufacturing process.By conducting thorough composite inspections at each step, such as material analysis evaluation inspections, inspection of dimensional accuracy during processing, and inspection of the processing surface, planning and specifications can be realized with higher accuracy.

Production staff is directly involved in the planning team to ensure plan repeatability

Regardless of the company or individual, we are often asked about problems and concerns regarding socks.

- “Current socks don’t fit my feet anyway”

- “I’ll get hurt soon”

- “Can you make such an unusual design?”

In this way, most people do not know what to do or do not know what to ask for.

For nearly half a century, we have been producing OEMs for major brands. Utilizing that technology and experience, we will solve all your worries from planning to manufacturing and realize products that will satisfy you.

As soon as the project is completed, mass production can be started as soon as the production line is assembled

Now, the number of “sock stores” in Japan is rapidly decreasing. The reason is “competition with overseas companies” that many manufacturing companies are facing.

What is important for all brands to survive

“How can users be satisfied?”

“A product you want to use again?”

This is the attitude of facing customers.

To get feedback from users as soon as possible, the fastest commercialization process is essential.

Trust and achievements

OEM baseball stockings boast a 40% nationwide share, and also produce stockings and wristbands from famous major leaguers and the fourth hitter in the domestic league.

We are committed to domestic production by professional craftsmen who have cultivated many years of experience, and pursue the “best comfort” in all products. For that purpose, we have an idea every day in our company, and we are preparing an environment where we can provide high-performance socks to our customers with the highest quality.

In charge of OEM supply and artist costumes of many famous manufacturers

It’s not fair to talk about the goodness of your company alone.

- “Why are you chosen?”

- “Is it better than other companies?”

From this perspective, it is also important to determine whether or not it has been evaluated by a third party.

We pride ourselves on having a certain reputation from an objective point of view, for example, providing OEM products for the famous domestic manufacturer ASICS and receiving orders for stage costumes by artists.

Stable supply is possible from a small number to a large lot

OEM production by major manufacturers is mainly in “large lots”, while stage costumes for artists are mainly in “high design and small lots”, and the characteristics differ greatly.

We have a reliable technology that does not depend on whether the number of lots is “large or small”, and we are launching products that can be safely viewed from a third-party perspective.

Currently, second generation expands business while taking over the business

Ueda Co., Ltd. is located in Koryo-cho, Nara.It is a town that has long been known as a “sock town”. In fact, Nara is Japan’s largest sock producing area. There are many companies like us that are involved in sock making.

For two generations, we have built a strong network with many manufacturers in the prefecture since our founding.

That is why Ueda’s greatest strength lies in the environment where it is possible to manufacture high-quality socks more efficiently and respond to customer demands such as delivery time and cost.

OEM and internal planning

Utilizing the “results” and “artisan skills” that we have built up in the previous generation, we are distributing our own brand “e-socks” as an original brand instead of the original OEM.

We are particular about new materials and touches, such as socks, arm warmers and belly bands, which are widely supported in our 30s and 60s.

We propose unprecedented socks that combine the high quality of “wear and wear” with the functionality that governs beauty and health.

Provide OEM to manufacturers

OEMs from major manufacturers need the ability to supply products with very high standards.On the other hand, in recent years, as competition with overseas companies continues to intensify, it is not possible to survive simply by supplying, and proposals for new “designability” and “functionality” are always required.

At our company, we not only secure our supply capacity, but also take the “challenge” of constantly grasping the trends of the times and improving our technological capabilities, and we believe that this point is highly valued.

The ability to “come with complex design products” that cannot be imitated elsewhere

We believe that our strength in handling even stage costumes for artists is based on our “certain technology” that can handle complex designs.

As society seeks “the only experience that can only be found here and now,” design responsiveness is essential to achieve this.

We provide all brands with high design reproducibility based on “patterns” and “materials” backed by unique technology.

Providing products to various sports teams and collaborative product planning with band members

In the sports industry, there is always a need to improve functionality and endurance.In the field of competitions, new challenges are constantly being created, and we believe that how you can reflect the athletes’ concerns in product development directly leads to protecting the athletes.

We believe that protecting athletes is a challenge for society as a whole.We will not only cooperate with well-known sports clubs, but also actively cooperate with our support team, and always provide feedback from the sports field. By setting up a system to take in, we will provide strong backup for players.